For years, high-solids silicone coatings have been the go-to solution for extending the life of flat roofs. They solved real problems: UV degradation, ponding water, and premature membrane failure.

But fluid-applied roofing systems have continued to evolve.

Today, the category has moved beyond single-coat solutions into fully reinforced, fluid-applied membrane systems that behave less like a coating and more like a true roof assembly.

That’s where modern fluid-applied systems — including those developed by Fluid Applied Roofing — represent the next step forward.

What Fluid-Applied Roofing Actually Is

Fluid-applied roofing is not a patch and not a temporary fix.

It’s a seamless, fully adhered membrane system that is sprayed or rolled directly over an existing roof once that roof has been properly evaluated and prepared. When cured, it becomes the new waterproofing layer.

No seams.

No laps.

No mechanical fasteners or tapes.

Removing those elements eliminates many of the most common failure points on traditional low-slope roofing systems.

From Silicone Coatings to Reinforced Fluid-Applied Systems

Traditional high-solids silicone coatings perform well, particularly when it comes to UV resistance and ponding water. But they are still, at their core, single-layer coatings that rely on surface thickness alone.

Modern fluid-applied roofing systems take the concept further by introducing reinforcement directly into the membrane itself, rather than relying on fabric rolls, seam tape, or secondary reinforcement steps.

This shift — from applied coating to reinforced membrane — is what defines the current evolution of fluid-applied roofing.

The Fluid Applied Roofing System Explained

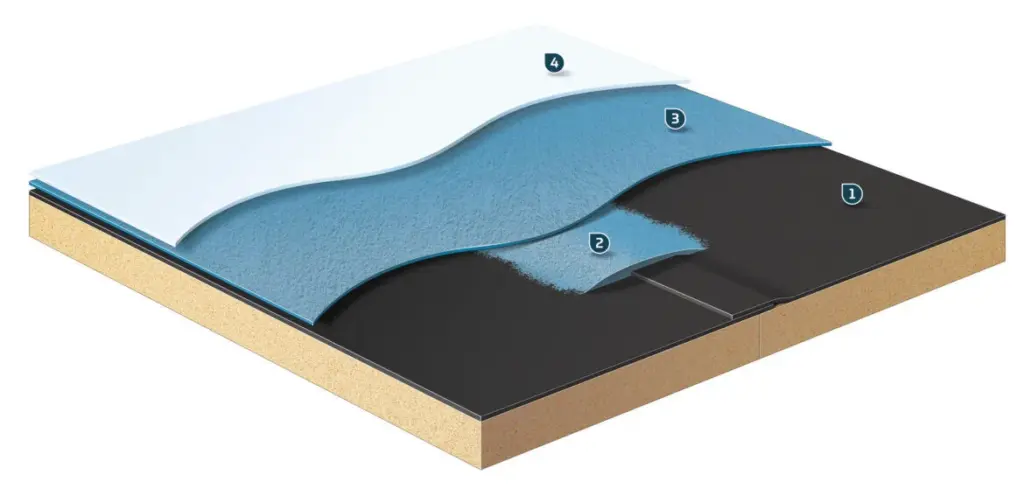

Fluid Applied Roofing uses a two-part fluid-applied system designed to create a reinforced, monolithic roof membrane that functions as a complete assembly.

The foundation of the system is the FiberSeal Base, followed by the ProCoat Finish.

FiberSeal Base

The FiberSeal Base is a spray-applied base layer that contains suspended fibers directly within the liquid formulation. Those fibers remain evenly distributed during application and cure into the membrane itself.

This is an extremely rare technical achievement in fluid-applied roofing.

Most systems that claim reinforcement still rely on external fabrics, scrims, or seam tapes that must be installed separately. With suspended fibers integrated into the chemistry, reinforcement becomes continuous across the entire roof surface, including seams, fasteners, penetrations, and transitions — without relying on secondary materials or perfect placement.

Once cured, the FiberSeal Base forms the structural backbone of the roof system.

ProCoat Finish

The ProCoat Finish is applied over the FiberSeal Base and becomes the exposed surface of the roof. It provides weather resistance, UV stability, and long-term durability while protecting the reinforced membrane beneath it.

Together, these layers function as a fully reinforced fluid-applied roof system, not simply a coating applied over an aging substrate.

Resetting the Clock: A New Warranty on an Old Roof

One of the most compelling advantages of fluid-applied roofing systems is the ability to put a new manufacturer-backed warranty on a roof that is already out of warranty.

Instead of tearing off the existing roof, owners can restore the waterproofing layer, reinforce weak points, and extend the service life of the roof — while placing it back under warranty.

That fundamentally changes the economics of flat roof ownership.

Less Invasive Than Replacement

Fluid-applied roofing systems are typically installed without a full tear-off.

That means:

- Minimal demolition

- Less debris and landfill waste

- Reduced noise

- Limited disruption to building occupants

For occupied commercial buildings, warehouses, retail spaces, and industrial facilities, this is often just as important as cost.

Performance Beyond Waterproofing

Modern fluid-applied systems deliver benefits beyond leak prevention.

Many are highly reflective, reducing roof surface temperatures and limiting heat transfer into the building. Over time, this can reduce HVAC demand and improve interior comfort, particularly on large roofs with heavy solar exposure.

These performance gains are measurable and cumulative.

A Strong Fit for Metal Roofs

Fluid-applied roofing systems perform exceptionally well on metal buildings.

Metal roofs tend to fail at fasteners, seams, and penetrations. A fluid-applied membrane encapsulates those areas into a continuous waterproof surface, dramatically extending service life and delaying replacement. This is all achieved without relying on taping seams due to the suspended fiber technology.

Tax Treatment: Often Classified as Maintenance

Because fluid-applied roofing systems are typically installed to extend the life of an existing roof, they are often classified as maintenance or repair, rather than a capital improvement.

In many commercial or business situations, that means the cost can be deducted in the year the work is completed, rather than depreciated over decades. In some cases, accelerated write-offs such as Section 179 may also apply, depending on the property and use.

Owners should always consult a tax professional, but the potential for first-year deductibility is a real advantage.

When Fluid-Applied Roofing Makes Sense

Fluid-applied roofing systems are a strong option when:

- The existing roof structure is sound

- The roof is out of warranty but still viable

- Minimizing disruption matters

- The goal is extending service life, not patching new failures

They are not a shortcut.

They are a strategic renewal option.

The Honest Takeaway

Silicone coatings were an important step forward for flat roofs.

Reinforced fluid-applied roofing systems are the next evolution.

By combining seamless application, suspended-fiber reinforcement, new warranty coverage, reduced disruption, improved building performance, and favorable tax treatment, fluid-applied roofing offers a third path between patchwork repairs and full replacement — and often outperforms both.